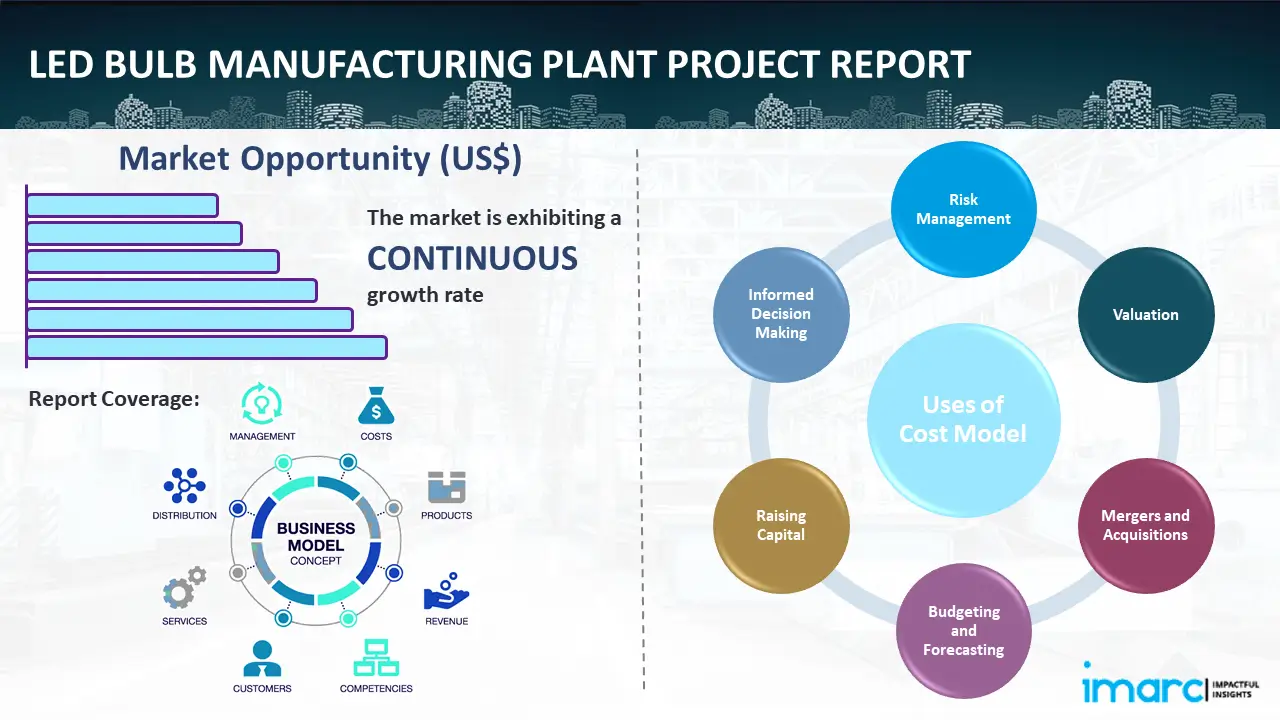

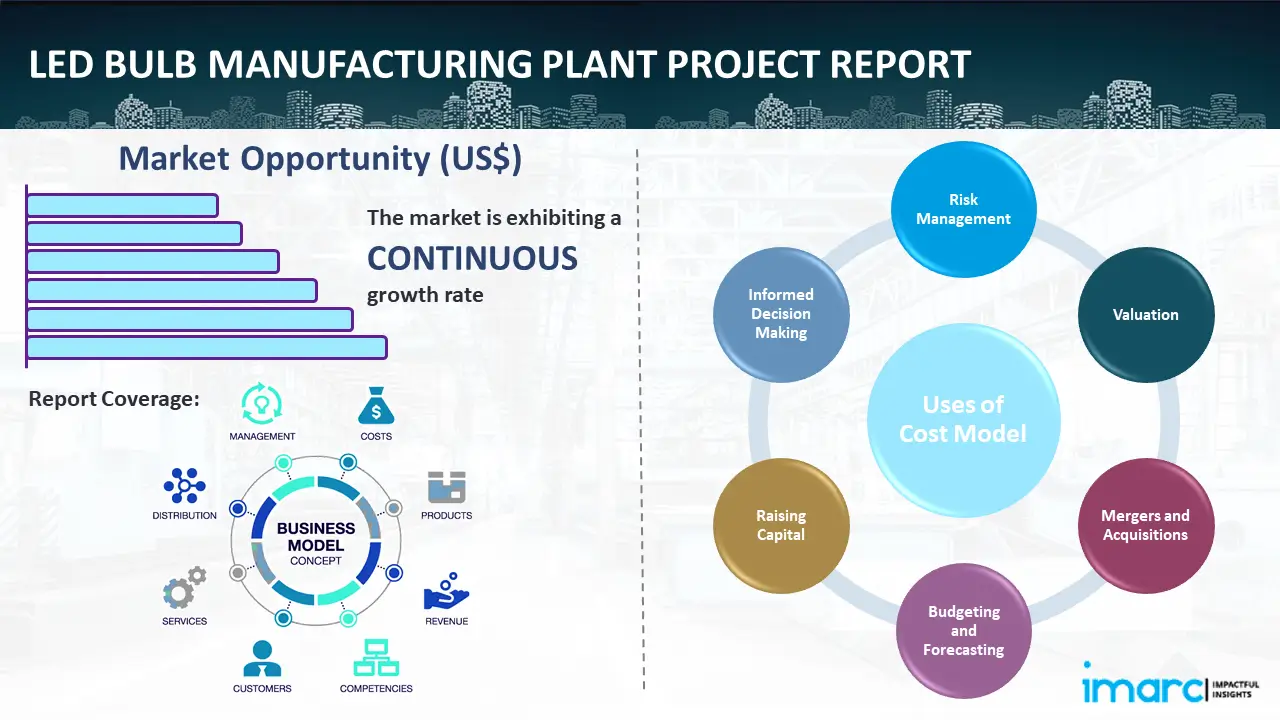

IMARC Group’s report titled “LED Bulb Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a LED bulb manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The report also provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

An LED bulb is a type of lighting device that uses light-emitting diodes (LEDs) to produce light. Unlike traditional incandescent bulbs that produce light by heating a filament, LED bulbs use a process that generates little heat and is much more energy efficient. LED bulbs are known for their long lifespan and low energy consumption, making them a popular choice for residential and commercial lighting applications. They are available in a variety of shapes and sizes, including bulbs that can be used to replace traditional incandescent bulbs in standard fixtures. LED bulbs are also environmentally friendly as they do not contain hazardous materials like mercury, which is often found in traditional incandescent bulbs.

The increasing demand for energy-efficient lighting solutions represents a significant factor driving the market growth across the globe. In line with this, consumers and businesses are increasingly seeking ways to reduce their energy consumption and costs, and LED bulbs provide a practical solution to this problem. This, in turn, is driving the market growth. In addition to this, rising environmental concerns and the increasing demand for long-lasting and cost-effective lighting solution is contributing to the growth of the market. Moreover, LED bulbs are free from hazardous substances, such as mercury, which is found in fluorescent and incandescent bulbs, thus increasing the demand for the product. Apart from this, governments of various countries implementing regulations and policies to promote energy-efficient lighting, such as phasing out incandescent bulbs is another key factor inducing the market growth. The market is also driven by the increasing construction in both developed and developing countries, coupled with government laws reducing the usage of inefficient lighting systems. The rising focus of LED manufacturers on features, such as Wi-Fi, occupancy sensors, and daylighting is boosting the market growth. Other factors, such as rising disposable incomes, increasing urbanization, and technological advancements are creating a positive outlook for the market.

The report provides a techno-commercial roadmap for setting up a LED bulb manufacturing plant. The study covers all the requisite aspects that one needs to know while entering the LED bulb industry. This report is a must-read for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the LED bulb industry.

The following aspects have been covered in the report on setting up a LED bulb manufacturing plant:

The report provides insights into the landscape of the LED bulb industry at the global level. The report also provides a segment-wise and region-wise breakup of the global LED bulb industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of LED bulb, along with the industry profit margins.

The report also provides detailed information related to the process flow and various unit operations involved in a LED bulb manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, and expenditure for setting up a LED bulb manufacturing plant. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

The report also covers a detailed analysis of the project economics for setting up a LED bulb manufacturing plant. This includes the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a LED bulb manufacturing plant.

| Report Features | Details |

|---|---|

| Product Name | LED Bulb |

| Report Coverage | Detailed Process Flow: Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements |

Land, Location and Site Development: Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs

Plant Layout: Importance and Essentials, Layout, Factors Influencing Layout

Plant Machinery: Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request)

Raw Materials: Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request)

Packaging: Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request)

Other Requirements and Costs: Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs

Project Economics: Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation

Financial Analysis: Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis

While we have aimed to create an all-encompassing report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include: